Ingenious DTF Printing Solutions: Enhance Your Clothing with Direct-to-Film Modern Technology

The Future of Fashion: Checking Out DTF Printing Modern Technology in the Fabric Sector

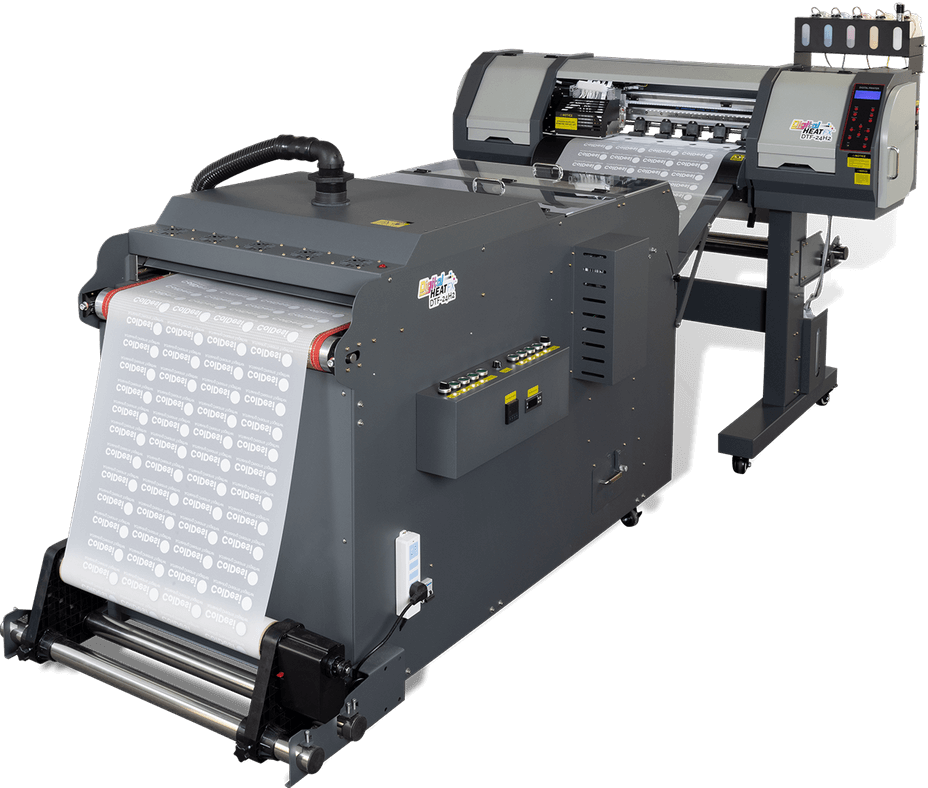

Among these advancements, Straight to Film (DTF) printing modern technology has arised as an encouraging competitor, providing one-of-a-kind capabilities and chances for developers and manufacturers alike. This sophisticated printing approach has sparked passion due to its prospective to revolutionize typical fabric printing procedures.

Development of Textile Printing

From the ancient worlds utilizing techniques like block printing to the digital revolution of today, fabric printing has actually consistently pushed borders. As the craft spread to other components of the globe, brand-new approaches such as screen printing and roller printing emerged throughout the Industrial Transformation, revolutionizing the fabric market.

In the 20th century, improvements in innovation led to the advancement of rotating screen printing, permitting faster and extra elaborate styles. The intro of electronic fabric printing in the late 20th century noted a substantial shift towards more sustainable and functional printing techniques. Today, with advancements like Direct-to-Fabric (DTF) printing technology, developers can develop dynamic, thorough prints with better performance and decreased environmental influence. The evolution of fabric printing showcases a rich history of imagination, resourcefulness, and technical progression on the planet of fashion and design.

Benefits of DTF Technology

With the advancement of textile printing methods from ancient approaches like block printing to modern technologies such as digital printing, the introduction of Direct-to-Fabric (DTF) technology has substantially improved the efficiency and sustainability of textile printing processes. Among the primary advantages of DTF modern technology is its capacity to directly publish designs onto material without the need for transfer documents, which minimizes waste and streamlines the production procedure. Additionally, DTF printing permits better color vibrancy and information accuracy contrasted to traditional approaches, allowing fabric suppliers to develop elaborate and top notch layouts with simplicity.

In addition, DTF modern technology is recognized for its versatility, as it can be made use of on different types of textiles, including all-natural fibers like silk, wool, and cotton, as well as artificial materials such as polyester and nylon (DTF Printing). This versatility opens up a wide variety of possibilities for manufacturers and designers to trying out various textures and materials, bring about more innovative and one-of-a-kind products in the apparel industry. Overall, the implementation of DTF modern technology represents a significant improvement in fabric printing, supplying many benefits that add to the future sustainability and creativity of the market

Sustainability in vogue Production

Stressing environmentally friendly practices is extremely important in contemporary fashion manufacturing, aligning with the expanding consumer demand for sustainable items. In current years, the style industry has dealt with boosting examination as a result of its substantial environmental influence, including extreme water use, chemical pollution, and textile waste. As a reaction, numerous fashion brand names are now incorporating sustainable methods right into their manufacturing processes to decrease damage to the environment.

Sustainability in vogue manufacturing incorporates various facets, such as using recycled and organic products, reducing energy intake, executing honest labor practices, and advertising openness throughout the supply chain. Furthermore, developments in technology, like DTF printing, offer chances to further boost sustainability in textile manufacturing. This innovation makes it possible for precise printing on materials, reducing ink wastefulness and water usage contrasted to typical printing techniques.

Design Flexibility and Personalization

In addition, DTF printing helps with personalization on a range formerly unattainable, permitting customized apparel and one-of-a-kind items customized to specific preferences. Customers can currently proactively take part in the style procedure, developing garments that reflect their design and personality. This personalization not only boosts the customer next experience yet also promotes a sense of exclusivity and individuality in a market saturated with mass-produced garments. Generally, DTF printing technology changes the layout landscape in the textile market, offering countless possibilities for innovative expression and personalized fashion.

Impact on Supply Chain & Market Trends

DTF printing modern technology in the textile market is improving supply chain characteristics and affecting market trends with its effectiveness and personalization capabilities. By making it possible for on-demand printing and eliminating the requirement for big stocks, DTF modern technology streamlines the supply chain process. Producers can produce products as required, decreasing waste and storage space costs. This just-in-time manufacturing version additionally permits for quicker action to market demands and trends, bring about a much more responsive and active supply chain.

In addition, the personalization possibility of DTF printing modern technology is transforming the marketplace patterns in the textile sector. Customers progressively look for distinct and tailored products, and DTF enables brand names to use bespoke designs cost-effectively. This customization ability not just enhances customer fulfillment but also opens up brand-new possibilities for services to provide to niche markets and separate themselves from competitors. Therefore, DTF innovation is driving a change in the direction of more customer-centric and innovative techniques within the fabric sector, forming the future of fashion.

Verdict

To conclude, DTF printing technology is reinventing the fabric market by using countless advantages such as layout sustainability, liberty, and personalization. This cutting-edge modern technology is reshaping the future of fashion production, affecting supply chains, and driving market fads in the direction of extra reliable and green methods. As the industry proceeds to develop, DTF printing will this play an important function in shaping the way fabrics are created and eaten in the years to come.

From the old people making use of techniques like block printing to the digital transformation of today, textile printing has actually continuously pushed boundaries. As the craft spread to other parts of the globe, brand-new approaches such as screen printing and roller printing arised during the Industrial Revolution, transforming the textile industry.

The intro of digital textile printing in the late 20th century noted a considerable change towards more lasting and functional printing techniques.With the advancement of fabric printing methods from ancient methods like block printing to modern-day developments such as digital printing, the introduction of Direct-to-Fabric (DTF) technology has actually considerably improved the performance and sustainability of textile printing procedures (DTF Printing).In reaction to the crucial shift in the direction of sustainability in fashion manufacturing, the adoption of ingenious technologies like DTF printing not only addresses environmental issues but additionally opens up avenues for unrivaled style flexibility and modification in the fabric market